产品特点:

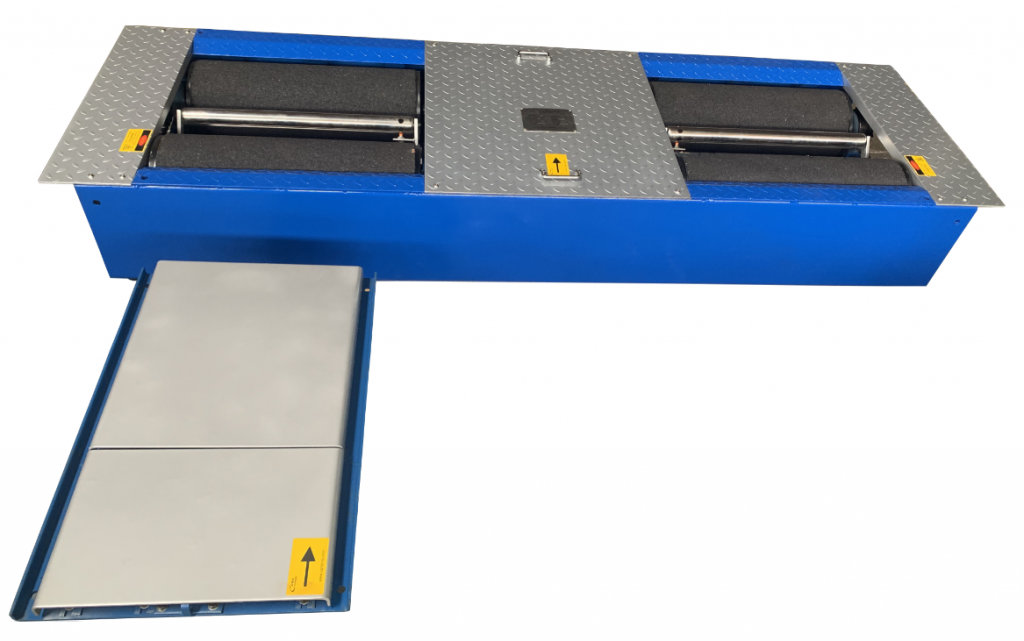

1、先进工艺生产的制动台粘砂滚筒,能保证20万次检测寿命,滚筒表面摩擦系数0.85以上,测试速度高达2.5 Km/h

2、汽车制动轴重复合检测台采用高效率自锁变速马达(3.0kw/380V),经久耐用,可升级为制动轮重复合检测台

3、汽车侧滑台具有轮胎侧向弹性力释放装置,有效提高检测汽车前轮侧滑量的精确度和准确性。汽车侧滑台可由单板侧滑台升级为双板侧滑台

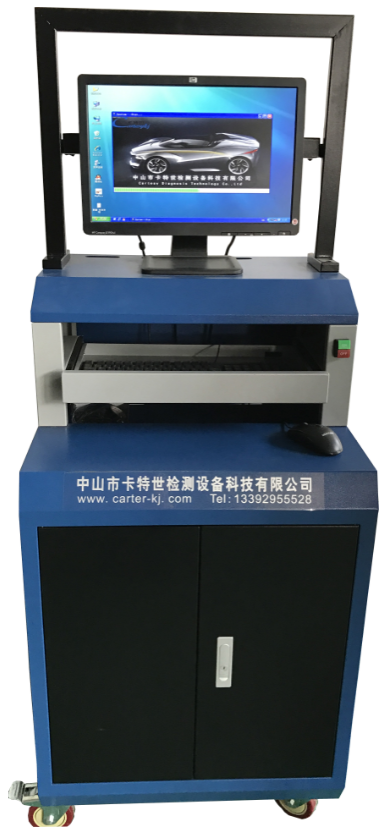

4、汽车检验台最大可通过轴载为4000kg的汽车; 使用工业控制计算机控制,自动流程操作、免教学

5、检测线可配置前照灯检测仪、废气分析仪、烟度计、声级计、监控摄像和联网接口等,所有检测结果通过一张报表显示

6、自主知识产权软件,检测系统可选择手动单工位、半自动、全自动操作检测

7、可自动打印并判定检测结果,可按时间、车牌、车型等自动快速查询检测数据和记录

8、系统内置最新的国家标准,用户可更改检测判定标准数值,可定制多种需求的软件,功能配置灵活。

9、系统信号数据采集极快,引车员脚踩刹车的同时,系统软件界面即可边绘画制动力过程曲线

10、满足GBT 16739-2014《汽车维修业开业条件》

| 序号No. | 项目Items | CTGT-3-3 | CTGT-3-3C | |

| 1 | 最大允许轴荷The max. axle load | 3000kg | 3000kg | |

| 2 | 适用轮距Applied wheel tread | 800-2200mm | 800-2200mm | |

| 3 | 电机功率Motor Power | 3KW*2 | 3KW*2 | |

| 4 | 电源Power supply | AC380V±10%50HZ | AC380V±10%50HZ | |

| 5 | 制动轴(轮)重复合检测台 Roller brake tester with axle(wheel) load | 滚筒直径Roller diameter | ∮245×700mm | ∮245×700mm |

| 滚筒中心距Roller center distance | 430mm | 430mm | ||

| 制动力测试范围Braking force test range | 0-1000N | 0-1000N | ||

| 示值误差Indicating error | ±3% | ±3% | ||

| 6 | 测滑台 Sideslip tester | 测试范围Test range | ±10m/km(单板single plate) | ±15m/km(双板double plate) |

| 示值误差Indicating error | ±0.2m/km | ±0.2m/km |

1, The sand-sticking roller of brake platform produced by advanced technology can guarantee the service life of 200,000 times, the friction coefficient of the roller surface is more than 0.85, and the testing speed is up to 2.5km/h

2, High efficiency self-locking variable speed motor (3.0kw / 380V) is adopted for the roller brake tester with axle load, and the product is durable and can be upgraded to the brake tester with wheel load

3, Sideslip tester with tire lateral elastic force release device, which check the car front wheel side slip in effectively improve the precision and accuracy. Automobile sideslip tester can be upgraded from single plate sideslip tester to double plate sideslip tester

4, Largest through- axial load is 4000 kg; Industrial control computer controlled

5, The test line can be equipped with headlight tester, gas analyzer, Opacimeter, sound level meter, monitoring camera, networking interface, etc., and all test results are displayed in one report

6, Independent intellectual property software, the detection system can choose manual single station, semi-automatic, full-automatic operation detection

7, It can automatically print and judge the test results, and can automatically and quickly query the test data and records according to time, license plate, vehicle model, etc.

8, The system is built-in with the latest national standards, users can change the value of detection and judgment standards, and can customize a variety of software requirements, with flexible function configuration.

9, The system signal data acquisition is very fast. When the driver steps on the brake, the system software interface can draw the brake force process curve at the same time

10, Meet GBT 16739-2014 automobile maintenance industry opening conditions

关注微信公众号!

关注微信公众号!