产品描述:

由平板制动检测台为主组成的汽车平板制动检测线是在模拟实际平坦道路的平板上,机动车以5到15 km/h的速度行驶其上,然后实施制动,一次性便可完成前(或后)轴动态测定制动力、轴(轮)重、悬架、侧滑等项目的检测。通过对制动板进行不同的组合,还可对汽车、摩托车、农用车等各种机动车进行多种制动性能的检测。我司引进欧洲最新技术制造的平板制动检测线,技术先进、设计合理、结构简单、性能稳定、使用维护方便、功能齐全、特别适用于汽车检测站,修理厂以及汽车专业教学和技术研究单位。

◆可无需做混凝土基础,直接地面安装,占地面积小、安装调试使用方便

◆不需380V动力电源,运行成本低,节能,节约投资

◆平板制动台的板块结构可通过多种组合以适合检测各种轴距之车型

◆平板制动台的板块的设计和工艺以及制造,符合最新国家标准GB21861和GB7258的规定

◆进口技术高精传感器,响应极快,测试快捷精确。产品 最新理念、超薄设计。

◆机动车在板上制动,模拟技术更接近实际路面情况,测试效果更真实可靠

◆系统配多种联机接口,可配前照灯检测仪及尾气分析仪等以组成多功能综合性能检测线

◆可采用四板组合,可使车辆前、后车轮同时测试,能准确反映前后车辆的制动同步情况,真实测试制动力特性曲线及整车制动协调时间

◆全自动工作方式

技术参数Technical parameters

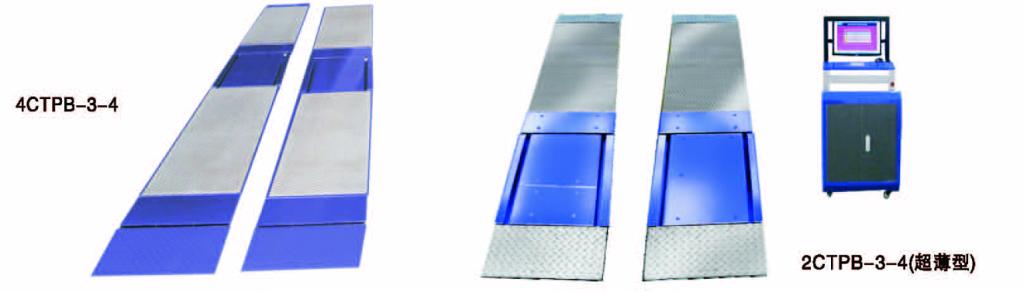

| 型号Model | 2CTPB-3-4 | 2CTPB-3-3 | 4CTPB-3-4 | 2CTPB-10 | 2CTPBH-10 | 2CTPBH-3-4 |

| 最大轴载质量(kg) Max. axle-load (kg) | 3000kg | 3000kg | 3000kg | 10000kg | 10000kg | 3000kg |

| 制动测试范围(kN) Braking test range (kN) | 10kN | 10kN | 10kN | 35kN | 35kN | 10kN |

| 侧滑测量范围(m/km) Sideslip Test Scope (m/km) | 0-±15m/km | N/A | 0-±15m/km | 0-±15m/km | N/A | 0-±15m/km |

| 制动力示值误差 Braking force error value | ≤±3% | ≤±3% | ≤±3% | ≤±3% | ≤±3% | ≤±3% |

| 侧滑测试精度(m/km) Sideslip test precision (m/km) | ≤0.2m/km | N/A | ≤0.2m/km | ≤0.2m/km | N/A | ≤0.2m/km |

| 轴重示值误差 Axle load error value | ≤±2% | ≤±2% | ≤±2% | ≤±2% | ≤±2% | ≤±2% |

| 称重板尺寸 Weighing plate size | 610*1500(宽*长) | 610*1500(宽*长) | 610*1500(宽*长) | 1000*1800(宽*长) | 1000*1800(宽*长) | 650*1500(宽*长) |

| 组合方式 combination | 2板/paltes | 2板/plates | 4板/plates | 2板/plates(选配4板/plates optional) | 2板/paltes(选配4板/plates optional) | 2板/plates |

| 检测车速(km/h) To detect the speed (km/h) | 5-10km/h | 5-10km/h | 5-10km/h | 5-10km/h | 5-10km/h | 5-10km/h |

| 电源(A) The power supply | 220v 300w | 220v 300w | 220v 300w | 220v 300w | 220v 300w | 220v 300w |

| 板尺寸(mm) Plate size (mm) | 2554×610×50 | 1760×610×50 | 4314×610×50 | 2854×1000×58(二板2 paltes) | 2440×1112×100 | 2790×746×80 |

The vehicle plate brake test line is mainly composed of plate brake tester, which is on the plate simulating the actual flat road. The motor vehicle runs on it at a speed of 5 to 15 km / h, and then implements the braking. The dynamic measurement of the front (or rear) axle braking force, axle (wheel) weight, suspension, sideslip and other items can be completed at one time. Through the different combination of the brake plate, it can also test the brake performance of various motor vehicles such as automobiles, motorcycles, agricultural vehicles, etc. Our company introduces the latest technology from Europe to manufacture the flat brake test bench. It has advanced technology, reasonable design, simple structure, stable performance, convenient use and maintenance, complete functions. It is especially suitable for automobile testing station, repair shop and automobile professional teaching and technical research unit.

◆No need for concrete foundation installation, small occupation of land, convenient installation and commissioning.

◆No need for 380 v power supply, low operating cost, saving energy, saving investment

◆The plate structure of plate brake tester can be combined in many ways to be suitable for vehicle types with various wheelbases

◆The design, process and manufacture of the plate of the flat brake tester comply with the latest national standards GB21861 and GB7258

◆With imported high-precision sensor, fast response, and accurate test. The latest product concept, ultra-thin.

◆Motor vehicle braking on board, the simulation technology is closer to the actual road conditions, and the test result is more real and reliable

◆System with a variety of online interface, can match headlight tester and the gas analyzer to form such as multi-functional integrated performance test line

◆Four plate combination can be adopted, which can make the front and rear wheels of the vehicle test at the same time, accurately reflect the brake synchronization of the front and rear vehicles, truly test the brake force characteristic curve and the brake coordination time of the whole vehicle

◆Fully automatic operation system

关注微信公众号!

关注微信公众号!