产品描述:

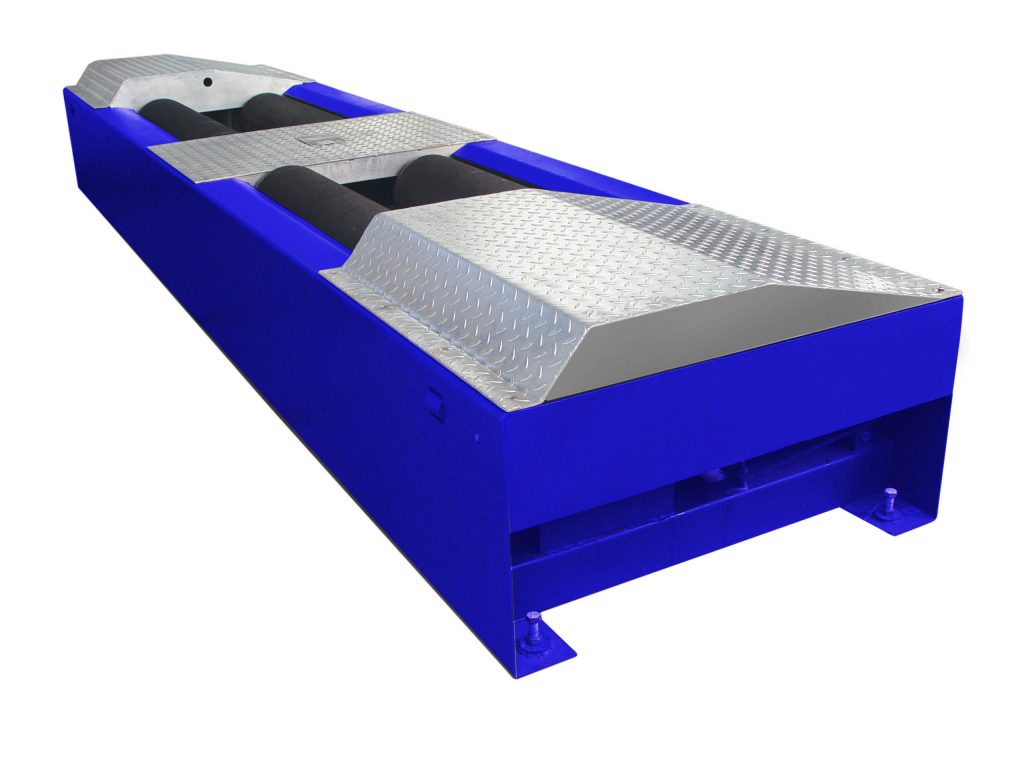

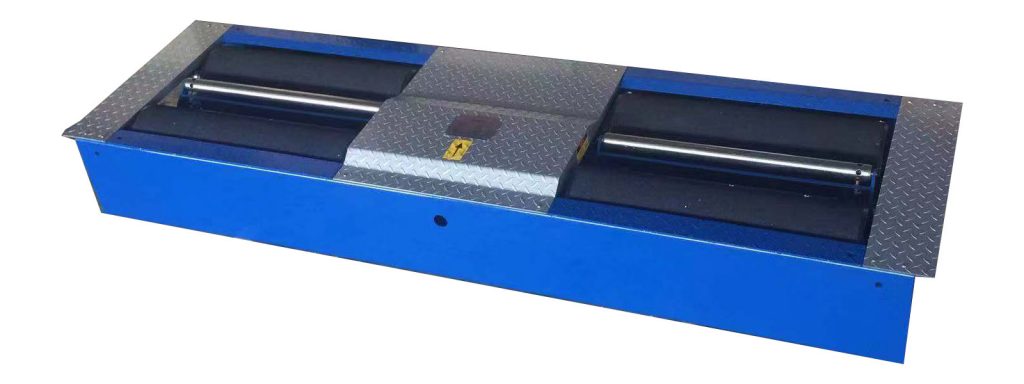

滚筒反力式汽车制动检验台是用于测量被检车辆各轴(左右轮)制动力的仪器设备。其主要用于额定承载质量下汽车制动性能的测试,可检测计算汽车各轴(左右轮)阻滞力,制动力及制动力差(过程差、最大差)、制动力与轴荷之比,以及手制动力与整车质量之比,同时加配踏板力计后还可检测制动踏板力及制动协调时间,记录和打印左右轮制动力曲线与踏板力曲线。该设备是机动车安全性能检测的核心部分,也是安全性能检测设备中技术性能要求较高的设备。

主要特性和特点:

◆机体采用整体焊接,强度高,无需地脚螺栓安装,调试方便

◆滚筒采用高强度砂粒沾结,强度高,可达20万次检测,附着系数≥0.85,示值误差<1.5%(国标≤±3%)

◆减速机为欧洲技术制造,电机、轴承、传感器等主要部件均为国内名牌产品,通过ISO9001国际质量体系认证

◆加装优质传感器,可组成制动轴重复合检测台,增加检测轴(轮)重项目,减少占地面积,节省投资

◆分带气囊举升装置和不带气囊举升装置供用户选择

◆分带第三滚筒和软件控制停机供用户选择

技术参数Technical parameters

| 型号Model | CTFZ-3 | CTFZ-10 | CTFZ-15 |

| 最大允许轴载质量(kg) maximum axle-load mass (kg) | 3000 | 10000 | 15000 |

| 轮距(内宽/外宽)(mm) Wheel base (width/wide) (mm) | 700(内)/2400(外) | 700(内)/2700(外) | 700(内)/2900(外) |

| 制动力测量范围(kN) Braking force measurement range (kN) | 2×(0---10) | 2×(0---30) | 2×(0---45) |

| 检测速度(km/h) Detection speed (km/h) | 2.5 | 2.5 | 2.5 |

| 滚筒直径*长度(mm) Drum diameter * length (mm) | ∮245×750 | ∮245×1000 | ∮245×1100 |

| 电机功率(kw) Motor power (kw) | 2×3 | 2×11 | 2×15 |

| 电源 The power supply | 380V 50HZ | 380V 50HZ | 380V 50HZ |

| 外型尺寸(mm) Installation dimensions (mm) | 2900×870×350 | 4100×1115×450 | 4100×1115×480 |

The roller brake tester is used to measure the braking force of each axle (left and right wheels) of the inspected vehicle. It is mainly used to test the braking performance of the vehicle under the rated load-bearing mass. The roller brake tester can test and calculation the each axis (eft and right wheels) block force of car, brake force and the deviation of brake force (process deviation, and maximum deviation), as well as the ratio of brake force and axis load , the ration of hand brake force and whole quality of the car. As the foot brake pedal pressure gauge is installed, the brake pedal force and the brake coordination time can be detected, and around round business power curve and pedal force curve can be recorded and printed. The equipment is core part of the motor vehicle security performance detection and the high technical performance requirements of safety testing equipment.

Main features

1. The main body is wholly welded, with high intension, no need to fix the main body on the ground with ground bolts and it is easy to adjust and install.

2. The rollers are covered with high quality surface sand, advanced adhesives and technology, the adhesion modulus is above 0.85 in case of both dry and wet, the longevity is over 200000 times. Test precision is high, repetition performance is good, brake force errors <1.5% (National standard <3%).

3.The reducer is manufactured by European technology, and the main parts of motor, bearing, sensor, etc. are all domestic famous brand products, which have passed ISO9001 international quality system certification and CE certification

4. It can be equipped with high-quality sensors to form a brake tester with axle load, increase the items of testing the axle (wheel) load of the vehicle, which will reduce the floor area and save investment that means no need to buy a axle(wheel) load tester.

5.You can choose the test bench with or without airbag lifting device.(The airbag lifting device is for the convenience of the vehicle entering and leaving the tester)

6. With automatic stop device, to prevent tire abrasion. We can provide two options: the third roller stop device and the software controlled shutdown.

The roller brake tester is used to measure the braking force of each axle (left and right wheels) of the inspected vehicle. It is mainly used to test the braking performance of the vehicle under the rated load-bearing mass. The roller brake tester can test and calculation the each axis (left and right wheels) block force of car, brake force and the deviation of brake force (process deviation, and maximum deviation), as well as the ratio of brake force and axis load , the ration of hand brake force and whole quality of the car. As the foot brake pedal pressure gauge is installed, the brake pedal force and the brake coordination time can be detected, and around round business power curve and pedal force curve can be recorded and printed. The equipment is core part of the motor vehicle security performance detection and the high technical performance requirements of safety testing equipment.

Main features

1. The main body is wholly welded, with high intension, no need to

fix the main body on the ground with ground bolts and it is easy to adjust and

install.

2. The rollers are covered with high quality surface sand, advanced

adhesives and technology, the adhesion modulus is above 0.85 in case of both

dry and wet, the longevity is over 200000 times. Test precision is high,

repetition performance is good, brake force errors <1.5% (National standard

<3%).

3.The

reducer is manufactured by European technology, and the main parts of motor,

bearing, sensor, etc. are all domestic famous brand products, which have passed

ISO9001 international quality system certification and CE certification

4. It can be equipped with high-quality sensors to form a brake

tester with axle load, increase the items of testing the axle (wheel) load of

the vehicle, which will reduce the floor area and save investment that means no

need to buy a axle(wheel) load tester.

5.You

can choose the test bench with or without airbag lifting device.(The airbag

lifting device is

for the convenience of the vehicle entering and leaving the tester)

6. With automatic stop device, to prevent tire abrasion. We can

provide two options: the third roller stop device and the software controlled shutdown.

关注微信公众号!

关注微信公众号!